An outstanding Ukrainian foundry scientist who made a significant contribution to the development and improvement of foundry production and the science of casting metals and alloys, Konstantyn Ilyich Vashchenko (1900 - 1992) entered the history of science and technology as a metallurgist-innovator and, at the same time, a talented engineer. For the first time in the USSR he developed the theoretical basis for the production of chemically stable alloys, founded a new direction in the theory of modification and technology for producing high-strength cast iron. K.I. Vashchenko also had a direct relationship with Igor Sikorsky Kyiv Polytechnic Institute - as his graduate and teacher. With extensive practical experience, he paid considerable attention to the quality training of young engineers and scientists for industry, trained 8 doctors and 80 candidates of science.

January 8, 2021 marked the 120th anniversary of his birth. Konstantyn Vashchenko was born in the town of Kozelets (now an urban-type settlement in the Chernihiv region) in a family of workers. He began his career at the age of 13 - he worked as a freelance builder. He graduated from Kozelets Parish School and Kozelets Higher Primary School. In 1919 he voluntarily joined the Red Army, until 1921 he headed the garrison school for the elimination of illiteracy, then worked as an inspector of Literacy and a teacher in Kozelka (until 1923).

After studying at the Kyiv Institute of Public Education (1923-1925), Konstantyn Vashchenko entered the Faculty of Chemistry. He studied the general course of metallurgy from a professor V.P. Izhevskyi (1863-1926) - the founder of the metallurgical specialty at Igor Sikorsky Kyiv Polytechnic Institute, and after Izhevskyi's death -from his student, a graduate of Igor Sikorsky Kyiv Polytechnic Institute in 1914, a corresponding member of the USSR Academy of Sciences, professor V.Yu. Vasyliev (1890-1956).

In those days, students were involved in active independent and practical work. V.Yu. Vasyliev gave intensive review lectures, and students independently conducted in-depth study of their speciality from literary sources and during internships in blast furnace and steel smelters, non-ferrous metallurgy plants, foundries of machine-building plants. This form of education was used to combine the theoretical work of students with the production and to obtain practical material for theoretical analysis. The main condition of production activity was compliance with the requirement that the student must be an employee, not a simple observer.

In 1930 K.I.Vashchenko graduated from Igor Sikorsky Kyiv Polytechnic Institute. He worked as an inspector of industrial training, assistant. In 1930-1934 he was a graduate student of the Department of Metal Technology. In those years, on behalf of the plant "Lenin's Forge" he wrote an applied scientific work "Establishing the regime of the process of small immersion." To write it, he studied the operation of the cupola and the converter. Based on these studies, own calculations and analysis of the literature, K.I. Vashchenko gave recommendations that gave the plant a significant economic effect. It was especially valuable that these improvements were implemented in production without a radical re-equipment of the shop and without scarce materials, moreover - using cheaper and more affordable materials. On this occasion, Professor V. Vasyliev wrote about his former student: "He showed the ability to perform complex research observations in a production environment.”

On the basis of this work K.I. Vashchenko defended his dissertation on the problems of processing cupola cast iron into steel for casting in small Bessemer converters on the topic "Study of the small Bessemer process” in 1934 and became a senior researcher at the Ukrainian Research Institute of Chemical Engineering.

In 1934-1941 he was an associate professor at the Kyiv Industrial Institute (KII, as Igor Sikorsky Kyiv Polytechnic Institute was then called). At the same time, from 1935 to 1941, he worked as the head of the metallurgical department and a CPL consultant at the UkrNDIkhimmash, later as a research engineer at the Bolshevik plant and head of the Department of Metal Technology at the Kyiv Aviation Institute.

Those were the times when the industry was in dire need of corrosion-resistant alloys. The most common and available for production were high-silicon alloys, in particular ferrosilide - an alloy resistant to acids. Their production in the early 1930's was new to the former USSR. In 1934, a group of Ukrndihimmash employees led by K.I. Vashchenko developed the technology and set up the production process of ferrosilide smelting. Vashchenko summarized the experience gained during this time in his work "Obtaining healthy castings from ferrosilide" (1935).

In the pre-war years, together with the workers of the Bolshevik plant, he introduced for the first time in the country the technology of casting parts of chemical equipment from corrosion-resistant cast iron. Thanks to his research, chemical engineering plants received the technology of making castings from alloys "ferrosilid" and "antichlorine", "high-chromium" cast iron. His scientific works were awarded at the All-Union competition of the All-Union Council of Scientific Engineering Societies for the best research work.

From 1938 Konstantyn Vashchenko worked with heavy-duty cast iron. At that time he repeatedly gave reports in Kyiv, Kharkiv, Moscow and Leningrad, in which he popularized, explained and offered to involve in production his method of obtaining high-quality cast iron, which at that time was the most progressive. Since 1941, he continued his research work in the field of obtaining high-quality modified cast iron from domestic materials by the original method of modifying liquid cast iron before pouring it into the mold. This experience has been applied in the defence industry.

From 1938 Konstantyn Vashchenko worked with heavy-duty cast iron. At that time he repeatedly gave reports in Kyiv, Kharkiv, Moscow and Leningrad, in which he popularized, explained and offered to involve in production his method of obtaining high-quality cast iron, which at that time was the most progressive. Since 1941, he continued his research work in the field of obtaining high-quality modified cast iron from domestic materials by the original method of modifying liquid cast iron before pouring it into the mold. This experience has been applied in the defence industry.

During the German-Soviet war, along with other KII staff, he was evacuated to Tashkent and enrolled as an associate professor at the Central Asian Industrial Institute (CII). He directed all his knowledge and experience to strengthening the defence capabilities of the state. Vashchenko became one of the first Soviet creators of a particularly durable gray modified cast iron, needed for the mass production of cast artillery mines, armoury, air bombs and other types of ammunition. The scientist invented a rational technology for its production without the use of then scarce modifiers and developed GOST 2611-44 "Castings of modified gray cast iron". And, of course, provided significant assistance to enterprises in the industry to implement this technology in production. He also participated in the design and construction of the Central Asian Metallurgical Plant. The contribution of the Ukrainian scientist was awarded the Order of the Red Star and the medal "For Valiant Work in the Great Patriotic War", and research of that time formed the basis of his doctoral dissertation "High-quality modified cast iron", which he defended in February 1944.

Personal file of Konstantin Ilyich Vashchenko, which is preserved in Igor Sikorsky Kyiv Polytechnic Institute, begins March 26, 1944 with a letter from the All-Union Committee for Higher Education under the Council of People's Commissars of the Soviet Union to the director of the Central Asian Industrial Institute. The document refers to the business trip of associate professor K.I .Vashchenko to a permanent job of restoring the Kyiv Industrial Institute (this was the name of the Igor Sikorsky Kyiv Polytechnic Institute at the time) and a statement dated April 25, 1944 from him to the director of the KII to come to work. Thus, he became one of the first specialists to return to Kyiv liberated from the occupiers and dedicate his activity to the reconstruction of the KPI.

And in December 1944 on the initiative of the Presidium of the USSR Academy of Sciences, and its head academician O.O. Bogomolets at institute, with the active support of the Vice President of the USSR Academy of Sciences, Academician I.P. Bardin, Corresponding Member of the USSR Academy of Sciences V.Yu. Vasilyev and rector of KPI O.S. Plygunov the new faculty was opened - metallurgy (later - engineering and physics, which became one of the faculties, on the basis of which the E.O. Paton Institute of Materials Science and Welding was recently established), the first dean of which was K.I. Vashchenko. He held this position for 15 years (from 1944 to 1959), at the same time heading the department of foundry production of ferrous and non-ferrous metals (1944-1974).

Despite the heavy administrative workload, he never stopped research. In the postwar years, he was able to summarize his scientific and practical experience in the monographs "Modified cast iron" and "Chemically resistant castings", which were published in 1946 in Moscow and was very popular among professionals. Due to this, the scientific authority of the department and its head was very significant not only in Ukraine but also in other republics of the former USSR.

As the dean of the faculty, K.I. Vashchenko paid a lot of attention to the improvement of educational work, selection, training and placement of pedagogical and scientific staff at the faculty. Thanks to his efforts, equipment was updated, including electric furnaces, microscopes, and laboratories.

The scientist made a significant contribution to the development of the department of foundry production, which together with the departments of metallurgy of steel and industrial furnaces, metallurgy of cast iron and the theory of metallurgical processes, metal knowledge and heat treatment was part of the faculty. He not only managed the research work of the department and the educational process at the faculty, but also provided technical assistance to enterprises of Kyiv. He acquainted students with the latest achievements of domestic science and technology, in lectures promoted the benefits, priorities of domestic science and the achievements of our scientists.

K.I. Vashchenko founded a school of foundry scientists in Ukraine. Its representatives are professors A.P. Syomyk, O.M. Byalik, O.P. Makarevych, S.P. Doroshenko, associate professors G.I. Koshovnyk, V.P. Avdokushyn, L.M. Syroporshnev, V.O. Kosyachkov, O.A. Tchaikovsky, M.M. Yamshinsky, R.V.

K.I. Vashchenko founded a school of foundry scientists in Ukraine. Its representatives are professors A.P. Syomyk, O.M. Byalik, O.P. Makarevych, S.P. Doroshenko, associate professors G.I. Koshovnyk, V.P. Avdokushyn, L.M. Syroporshnev, V.O. Kosyachkov, O.A. Tchaikovsky, M.M. Yamshinsky, R.V.

February and others. Vashchenko worked fruitfully with his students in the field of research into the nature of the liquid state of metals and alloys; interaction of liquid metal with the form; processes of modification and refining of cast irons, steels and non-ferrous alloys; development of wear-resistant and heat-resistant high-alloy steels and alloys; obtaining bimetallic castings. The novelty of his technical solutions is confirmed by 30 copyright certificates.

Among his students and pupils there are many representatives of other states. He was awarded the Order of Friendship of People for training scientific and engineering personnel for Bulgaria, Germany, Cuba, Poland, Romania, Hungary and other countries.

Developing in the postwar years work on the study of high-strength cast iron, he made a significant contribution to the theoretical foundations of magnesium cast iron with spherical graphite and the introduction of this new and valuable structural material in industry. Due to this, the production of such cast iron in the early 1960's amounted to 10% of total iron production. And in 1957, together with his student Laurentius Sofroni from Romania, he prepared a monograph "Magnesium Cast Iron", which actually analysed, systematized and summarized almost all world and domestic literature on the subject (over 600 sources) and presented the results of original research of K.I. Vashchenko and his school, which gave unambiguous answers to controversial questions of theory and practice.

As a recognized specialist, K.I. Vashchenko repeatedly participated in international congresses and conferences, as well as went abroad to give lectures on foundry production, in particular in 1957 he was in the GDR and in Spain, in 1962 - in West Germany and the GDR.

In 1960, after relocating the foundry of the Lepse plant from the premises of university to the new territories, the vacated premises were transferred to the department of foundry production with free left, relatively modern as in those years shop equipment. On their basis in 1961 a foundry laboratory equipped with the necessary equipment for student training and research of the department with an area of 1600 square meters was created. Teachers and staff of the department were given a wide opportunity to conduct relevant experimental research in order to develop new and improve traditional technological processes of casting. The full technological cycle of casting was reproduced on the laboratory equipment. Thus, the quality of practical training of foundry students was raised to a much higher level. In 60s K.I. Vashchenko managed the basic foundry laboratory of KPI, which provided significant assistance to industry. Since 1966, the laboratory has cooperated with the Ministry of Construction, and since 1989. - with the Ministry of Hard Machinery of the USSR and the Ministry of Energy of the Ukrainian SSR.

Together with the Kyiv Motorcycle Plant, the Department of Foundry conducted a study of the processes of obtaining bimetallic castings, which give a significant effect in the operation of internal combustion engines with air cooling. Thanks to these studies, Kyiv Polytechnic Institute has made a significant contribution to the improvement of K-650 motorcycle engines (MT-8 - MT-12). Under the leadership of K.I. Vashchenko, the technology of casting the engine crankshaft from high-strength cast iron was developed, the technology of casting the crankcase was improved, the technology of making bimetallic piston sleeves was developed, thanks to which the reliability of the engine was increased almost twice.

Based on the research of the department headed by him, the scientist proposed original changes in the production of ferrosilide at the Bolshevik plant, the introduction of which allowed to reduce the smelting time and obtain a high yield of suitable metal.

In the 60's at the department, which was headed by a professor K. I. Vashchenko, were carried out researches of processes of modification, microalloying and refining of pig-iron, steels and non-ferrous alloys; study of the nature of the liquid state of metals and alloys (surface tension, non-metallic inclusions, gas content, etc.), study of the interaction of metal with the form, study of liquid (bulk) self-hardening and other mixtures with their subsequent introduction into foundry production. At the same time, he successfully managed the pedagogical work of the staff of the department and, at the same time, gave a course of lectures on cast iron for students.

In 1964 K.I. Vashchenko was awarded the title of "Honoured Worker of Science and Technology of the USSR.” The presentation from KPI to this award emphasized: "Developing in the post-war years work with high-strength cast iron, made a great contribution to the theoretical foundations of magnesium cast iron with spherical graphite and the introduction of this new very valuable structural material in the industry.”

In 1973, under his leadership, the department developed and put into production an installation for rapid determination of gas content directly in the molten metal.

For his colleagues and numerous students, Vashchenko became a model scientist, organizer and public figure. Konstantyn Ilyich was a member of the editorial boards of the magazines "Foundry Production", "Technology and Organization of Production"; member of the editorial board of the "Mechanical Engineering"; was a member of the councils for the defence of doctoral and candidate dissertations at the KPI and the Institute of Lithuanian Problems of the USSR Academy of Sciences. He also headed the foundry section of the Kyiv branch of Mashprom, was chairman of the expert commission on metallurgy of the Ministry of Higher and Secondary Special Education of the USSR, member of the Scientific and Methodological Council of the Special forces of the USSR, member of the Council of Scientific and Technical Expertise, head of the commission of foundry production of the State Scientific and Technical Committee of the Council of Ministers of the USSR, chairman of the problem commission of the section "Processes of casting" of the USSR Academy of Sciences.

Konstantyn Ilyich worked at Igor Sikorsky Kyiv Polytechnic Institute until his last days. Within the walls of his alma mater, he celebrated his 85th birthday, and in 1990 he celebrated the 60th anniversary of the beginning of his work at the institute.

He is the author of more than 450 scientific papers, including 37 monographs and textbooks. The last published work of K.I .Vashchenko in co-authorship with V.S. Shumikhin "Melting and out-of-furnace processing of cast iron for castings", published in 1992, and to this day remains the main textbook for students of metallurgical departments of universities in the discipline "Cast Iron Casting" .

He is the author of more than 450 scientific papers, including 37 monographs and textbooks. The last published work of K.I .Vashchenko in co-authorship with V.S. Shumikhin "Melting and out-of-furnace processing of cast iron for castings", published in 1992, and to this day remains the main textbook for students of metallurgical departments of universities in the discipline "Cast Iron Casting" .

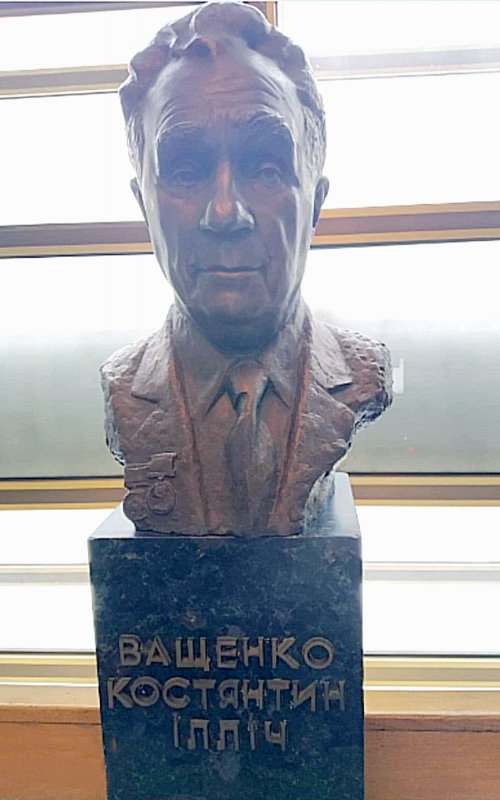

The memory of K.I. Vashchenko is honoured and preserved in the Igor Sikorsky Kyiv Polytechnic Institute. And in the lobby of the Paton Institute of Materials Science and Welding there is his bust.

Lyudmyla Bashtova, SPM at Igor Sikorsky Kyiv Polytechnic Institute