How are ideas for developing a new technology and tool born? This question arises when you get acquainted with the materials of fundamental and applied research, which are carried out simultaneously with the educational process on the basis of two departments of the Educational and Research Institute of Materials Science and Welding named after E.O. Paton ( Institute of IMZ) of Igor Sikorsky Kyiv Polytechnic Institute - the Department of Physical Materials Science and Heat Treatment (FMTO) and the Department of Laser Engineering and Physical and Technical Technologies (LTFT).

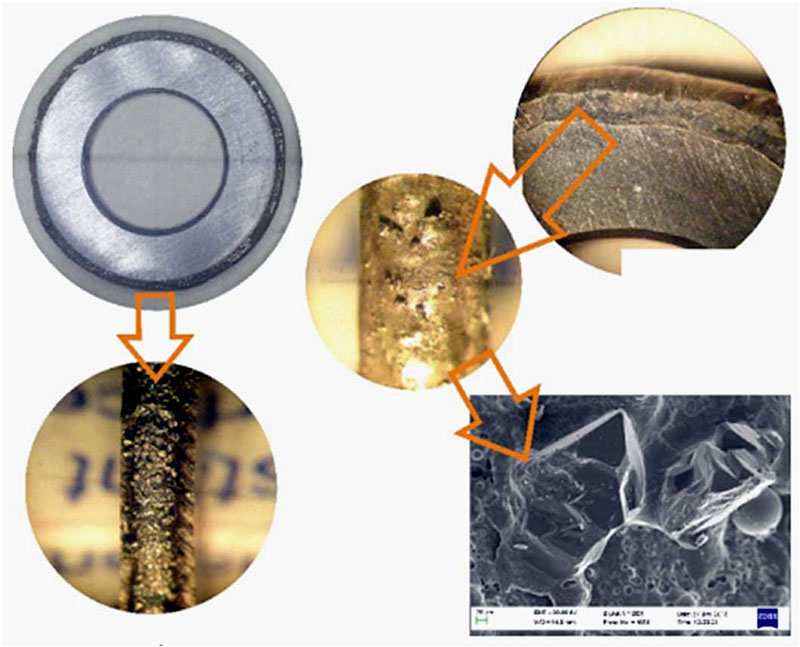

The project is about the synthesis of diamond-containing composites using the process of thermal deformation laser sintering for abrasive processing of large parts used in aircraft, shipbuilding, and mechanical engineering.

Oleksii Kahliak, Head of the LTFT Department, told us in detail about the history of this project.

💥

- Oleksii Dmytrovych, you are the responsible project manager. And who is its supervisor? Was the project application supported by the National Research Foundation of Ukraine (NRFU)?

- The scientific advisor of our project is Professor Svitlana Voloshko of the FMTO Department. The application was supported by the National Research Foundation of Ukraine within the framework of the competition for research and development projects “Science for Strengthening Ukraine's Defense Capabilities”. The project will last for two years. The application was highly rated by experts - 95.4 points. In terms of the number of points, our project application took second place among more than 80 projects that were recognized as winners of the competition and received funding from the NRFU. Such a high result is due to the combination of the potential of two powerful scientific schools founded by well-known scientists - Academician of the National Academy of Sciences of Ukraine V. Hrydnev and Member of the International Engineering Society (CIRP) V. Kovalenko.

- How did you come up with the idea of manufacturing advanced grinding and cutting abrasive tools?

- Traditional methods of forming tool layers with superhard abrasive materials, such as electroplating, bulk sintering of superhard composites, etc., have serious technological drawbacks. For example, due to the insufficient strength of the material grains and the long duration of the manufacturing process, reliable equipment cannot be produced. At the same time, the demand for grinding and cutting abrasive tools remains high. It is the use of laser synthesis technology for composites containing abrasives in their structure that will significantly reduce tool manufacturing time and improve their operational level. The project is primarily aimed at developing and manufacturing an experimental sample of a new original tool design to improve the efficiency of abrasive processing of large-sized sheet products used in strategic industries for the defense industry of Ukraine. However, in order to select the optimal processing modes and technological schemes, it is necessary to establish the regularities of changes in the thermal state during laser irradiation of such a complex system as a powdered multicomponent binder - diamonds - steel tool body - forming matrix. To limit, as they say, the search field for such regularities, it is planned to use simulation of the sintering process based on the developed theoretical model and conduct a wide range of experimental studies. As a result, it is planned to achieve a significant increase in production productivity, as well as a reduction in cost and energy consumption in the manufacture of tool composites with superhard materials of various types, including synthetic diamonds, to ensure a controlled distribution of abrasive grains in the working layer of the tool and thus reduce diamond consumption, as well as significantly expand the range of tools.

- So the importance of implementing this project is not only in its scientific and practical component, but also in its economic attractiveness?

- Indeed, according to our colleagues, the proposed concept of manufacturing such a tool will provide a significant economic effect by significantly reducing the downtime of industrial equipment associated with replacing the currently used tool, which, unfortunately, wears out quickly.

- Oleksiy Dmytrovych, will the whole complex of research and development be implemented at the E.O. Paton Institute of IMZ?

- Yes, on the basis of the Department of LTFT using gas and solid-state lasers of continuous and pulsed action. The research will also take place at the experimental base of the Center for Collective Use of Scientific Equipment “Materials Science of Refractory Compounds and Composites”. Upon completion of the project, all the equipment that is planned to be purchased, in particular a welding machine based on a 1500 W fiber laser, will be used in the educational process of Igor Sikorsky Kyiv Polytechnic Institute to train specialists in the educational programs “Engineering of Welding, Laser and Related Technologies” and “Engineering and Computer Modeling in Materials Science” at three levels of higher education, as well as during research at the departments of FMTO and LTFT.

- Will students be involved in the preparation and implementation of the project? Which scientists will work on it? Is the laboratory and technological base sufficient to develop a new type of instrument?

- The project will involve third-degree students. The laboratory facilities available at both our departments are sufficient for the initial stage of research. Since the project covers a wide range of interdisciplinary issues and involves both a theoretical component and the development of a number of technical and design solutions, our team of performers was formed on the principles of mutual complementarity of scientific interests and age balance. Among the authors, in addition to me, are Svitlana Voloshko, winner of the 2021 Borys Paton National Prize, Leonid Holovko, professor of the Department of LTFT, Oleksiy Goncharuk, associate professor of the Department of LTFT, as well as young students of scientific schools - Oleksandr Danyleiko (LTFT) and Andriy Burmak (FMTO).