In December 1881 Swiss businessman Jacob Grether, who lived in Kyiv, bought from the heirs of Colonel Leonovich the right to lifetime use four tithes (about 4.4 ha) state land on the western outskirts of Kyiv - Shulyavka. Together with Hessen citizen, engineer Philip Moser on this site July 26, 1882 (New Style) Grether opened a new venture - an iron cast and mechanical plant. The company begun producing beds, a simple cast iron fittings, refineries forms, filter presses, bolts, nuts, staples and other fasteners.

First, the plant employed 30 employees. Complex products were not made, because the equipment was too primitive - 2 cupola furnaces and a few simple tools. Energy power of the company was estimated in 1620 horsepower. However, the owners have chosen the direction correctly, conditions evolved very well. For quite a short period of time the annual production capacity of the plant has reached 100-165 thousand rubles. But, obviously, the profit distribution caused conflict between companions, and in 1888 Philip Moser, who served as well as acting director and, came out from the business and went abroad. In his place Grether invited citizen of the Austro-Hungarian Empire, a graduate of the Prague Polytechnic Institute Joseph Krivanek. Together with Krivanek an another engineer specialist in steam boilers Ferdinand Vitachek came to Kyiv. They became co-directors of the new company, established on the basis of "Kyiv cast iron mechanical plant» issued as a "partnership on trust" (something like a limited liability company) - Joint Stock Company "Kyiv engineering and boiler plant Grether, Krivanek and K° 'with capital of 1 million rubles. Such a strong economic foundation of a new society created contributions not only the founders of the company, but for less significant shareholders: German, Swiss and Czech entrepreneurs E.Lidke, V.Kuksha, X.Gedekera, I.Otta and others. Jacob Grether again became the chairman of the society. And engineering and technical secondary structure of the enterprise was staffed originally from the Czech Republic. From there some highly skilled workers were invited to work in Kyiv.

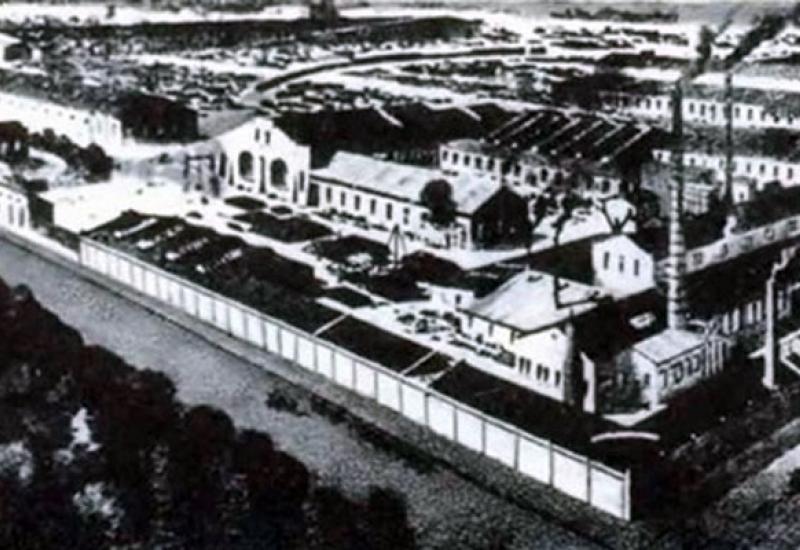

A radical reconstruction of the plant begun in 1890. Soon the iron, boiler, lathe, model, forging and refinery became its main shops. The main area of work was the production of equipment for processing and food industries (primarily - for sugar), equipment for brick and mills, as well as the release of various tanks, pumps, iron and copper casting, refinery shapes and transmissions.

Within a short time the plant became one of the largest in the industry and in the city. Suffice to say that at the end of the XIX century they were worked on it up to 900 employees. In number, he conceded only to Kyiv's main railway workshops. Already in the 1893-1894 the cost of manufacturing at the plant Grether and Krivanek products amounted to about 50% of the cost of production of machine-building enterprises of Kyiv combined.

In 1896, the plant received a gold medal at the Fair, which was held in Nizhny Novgorod, for the steam engine of a new design, which was exposed there.

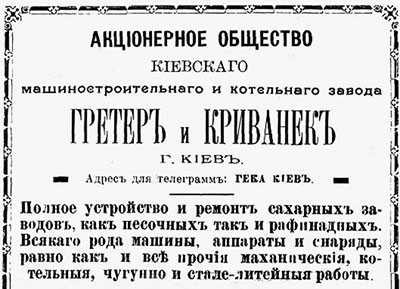

From advertising in 1899 it is clear that it was a very powerful plant. We must pay tribute to the members of the Board and management: they closely monitor the technical innovations and introduce modern technologies. So in 1903 the factory was again modernized – on the German project it was built open-hearth furnace with oxygen melting, a few years later - the assembly hall and the "material store" (as then called the factory warehouse).

Shortly before that, in 1902, Grether and Krivanek thanks to their great technical capabilities and the promotion of high officials won the tender for the manufacture of roof structures for the building under construction of the Kyiv office of the State Bank on the street Instytutska.

Plant Grether and Krivanek became almost a monopoly in the supply of equipment for sugar mills. Among the main clients of the company they were such sugar giants, as the Society of sugar refineries of brothers Tereshchenko; Grushevskii and Smolensk plants of earls Bobrinskys, sugar mills brothers Brodsky. But Grether not satisfied by one "sweet" industry. He just pays attention to railway construction, which swirled around a huge money in those days. The factory started making rails and suspension bridges, which were delivered on the Moscow-Kyiv-Voronezh Railway, Kyiv Bahn, Polish and Mykolayiv railways.

This rapid progress was not cheap for workers. Shift for workers of the main specialties at the plant Grether and Krivanek began at six in the morning and ended at half past six in the evening, sometimes even later. Machinists of steam engines had to begin work even earlier - five in the morning and leave it at seven in the evening - after the completion of the work in all areas. However, not always the workers have enough time to to perform a certain rate, and they were left on after working hours. By the way, this practice was widespread and according to factory inspection at the Kyiv factory districts in 1899 56.5% of all workers worked on extracurricular 208.9 hours instead of 120 hours permitted by law. The average salary at the plant Grether and Krivanek was in those years working for major specialties 30-35 rubles. The student teenage earn up to 7 rubles. And the master received 130 rubles in a month.

Management backbone of the plant was consisted from the Czechs. Krivanek was interested in attracting qualified personnel and their fellow countrymen. In the Russian Empire at that time there was a shortage of engineers. Foreign managers were always pricey, and the owners of the plant were forced to become generous to give a respectable salary (sometimes ten times higher than the rest of the staff) for specialists from abroad. At the same time entrepreneurs understand the prospects of local education. Their company had some relation to appearance Polytechnic Institute in Kyiv. Its main building is erected in 1898 by Warsaw firm "Kuksha and Liedke", whose owners were both shareholders and the plant Grether and Krivanek.

Grether and Krivanek not content with only Ukrainian market. It was time to create a company of empire-wide scale. But without representation in St. Petersburg and reliable capital charge d'affaires it was impossible to achieve the success. It was needed someone known in official circles and among the St. Petersburg business elite. They found Ryngold Kalning, who had the reputation of a very influential person. He began working with Grether and Krivanek at the time of flowering of their businesses - about 1908. Consulting services Ryngold Kalning were expensive - each year about 19 thousand rubles (according to the data of 1909). Management of the plant was inundated with letters from the representative of the capital with offers to take part in one or another lucrative tender. In addition, Kalning was involved in the supply of industrial raw materials to the plant. And sales are often not carried out from Kyiv, but through the St. Petersburg office Kalning. He paid great attention to print advertising. In 1910 he posted information about the production plant nomenclature Grether and Krivanek in the prestigious Journal of capital "indicator on domestic and foreign trade and industry."

After the revolution of 1917 holders of the plant, understanding the length of economic and the inevitability and political crisis, sold the company and left Ukraine. At a meeting of shareholders held in December 1918, the name Grether was not appeared anymore. Then the shareholders' meeting and all went out of fashion. Plant Grether and Krivanek Bolsheviks nationalized and named it in 1919 "The first state machine-building plant" and the anniversary of the revolution in 1922 gave him the name "Bolshevik", which he retained to this day.

The company was developing rapidly. Since 1926 the plant introduced a new process - welding. Here academician Paton begun his research of electric future. He was at the time - Professor KPI. Welding laboratory "Bolshevik" became the primary basis for the creation of the world-renowned E.O. Paton Institute of Electric Welding NAS of Ukraine.

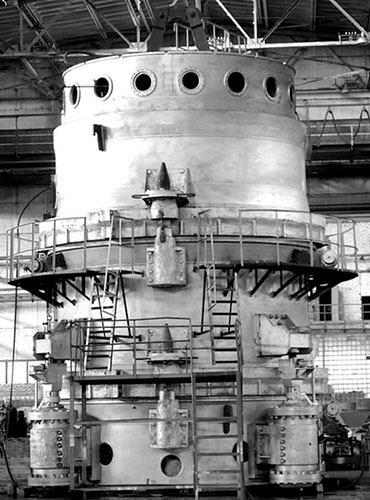

Since the 1930s. Plant chose its strategic "profession" - production of equipment for the chemical industry. At this time there is created the first Soviet equipment for synthetic rubber plant, which manufactured the first Soviet automobile tires. Delivery of products for export begun. Factory workers K.I.Vaschenko, I.S.Grigorev, B.D.Grozin, V.I.Dyatliv subsequently become prominent scientists. In the 1935-38 Chief engineer of the plant was N.O.Dollezhal in the future - the chief designer of the nuclear reactor, winner of the Lenin and State Prizes of four, Hero of Socialist Labor.

In 1939 the plant begun production of artillery shells, and since the early days of World War II as a defense enterprise, it was subjected to severe bombing of Nazi aviation. Evacuated to the Urals, the company has since 1942 established the mass production of 122-mm mortars, gave rise to the now famous "Uralkhimmash" ( Ekaterinburg, Russia). November 7, 1943, a day after the liberation of Kyiv, the plant as the company's Commissariat mortar weapons resumed its work.

The invaders destroyed it completely, including foundations, engineering and underground utilities. Yet already in 1948 the plant was revived and has reached the pre-war capacity for the production of chemical, and then - polymer equipment.

1950-60-ies were distinguished by a special rise in the development of the enterprise. Highly educated young professionals came annually at the plant. Basically, they were graduates of the Kyiv Polytechnic Institute. It was created a special design bureau of polymer engineering (SKB polimermash), Research Institute "UkrNIIplastmash" which became the leading developers of polymer equipment in the former Soviet Union. On the basis of these organizations and the plant it was organized Research and Production Association "Bolshevik". The former head of the Economic Council of Lviv Peter Y. Kostin (graduate KPI) was appointed as the first General Director. Under his dynamic leadership for nearly 10 years the plant was rebuilt, expanded, technically rearmed.

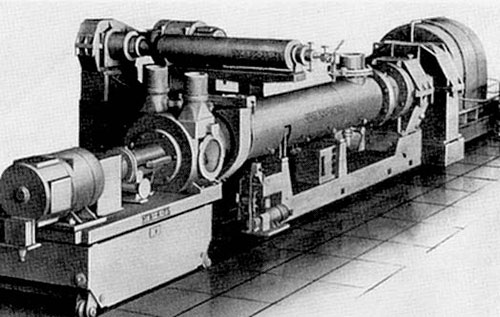

P.Ya.Kostin was replaced in 1974. A talented engineer and production manager, former deputy director of the plant "Lenin's smithy" Vitaly Izvekov (graduate KPI) came to leadership of the plant. He completed the reconstruction of the plant. During his stay as the general manager a score of new equipment, including the unique one , the first in the USSR and in the world was started in the plant.

In the 1980s the collective NPA "Bolshevik" designed and manufactured a set of equipment for the production of large (up to 5 m) diameter tires for dump trucks and avto-trains carrying capacity up to 220 tons. For this work, a team of designers, engineers and other specialists was awarded the State Prize of the USSR Council of Ministers. During these years, specialization of the company is expanding rapidly. The plant was working also on orders from the Ministry of Defense, which is more than 20% of total production. The geography of deliveries is expanded significantly. In the list of consumers of the products within the USSR were included 19 tire plants, 60 plants of rubber products, 15 cable plants, 24 enterprises of building materials, 33 plant for plastics processing, chemical plant and 21 others. The plant exports its goods to the countries of Eastern Europe, the USA, France, Denmark, England, Germany , Austria, Cuba, India, the Republic of Sri Lanka, China, Vietnam, Yugoslavia and other countries.

In 1990-ies after the collapse of the Soviet Union, the state of the consumer market products for the platn "Bolshevik" was changing dramatically for the worse. Disappear The orders for defense purposes disappeared. The economic crisis in Russia, other CIS countries leads to a significant drop in demand for the products of the association. During the first half of 1993 alone exports to Russia fell to 14.5 times compared with the previous year and reached almost zero. As a result, in the period from 1993-95 "Bolshevik" plant was on the verge of a full stop. A prolonged economic crisis begun. NPA "Bolshevik" as a single structure falls, and on its basis in 1996 the Open Joint Stock Company "Research and Production Enterprise" Bolshevik " was created. One hundred percent of its shares is owned by the state. The efforts of the company's management, headed by a former chief engineer, Victor Kuzmich Reshetov, to establish a marketing management lead to the appearance in 1996 signs of stopping the decline in production, and in 1997- some improvements. Then the volume of production gradually increased, markets expanded. Certification of production plant in accordance with the rules of the American Society of Mechanical Engineers (ASME) in the late 1990s give the possibility to deliver in the United States a large batch (13 units) shaper-vulcanizer large tires. To increase the production, plant is expanding its specialization through the development of new products, which would allow Ukrainian enterprises to avoid the import of cars from Russia and other countries. It was mastered the production of sawmills, mobile drilling plants, other oil field equipment.

The plant also manufactures products for the needs of the Kyiv on the City State Administration orders. It mastered the production of a new generation of escalators that reduce energy consumption by 30%, metal and labor - 30%. 2 of escalators were installed in the underpass at the Independence Square, 4 – were mounted at the metro station "Akademgorodok". It was made the first in CIS Tunnel complex, which makes it possible to build metro tunnels in unstable, water-saturated soils. The complex is 3-4 times the rate of penetration increases, reduces the cost of subway construction, eliminating the need for the destruction of urban development over the highway, drilling from the surface of soil freezing expensive, costly manual labor. Given the shortage of oil resources in Ukraine, of great economic and ecological importance will be achieved by the introduction of equipment, manufactured in "Bolshevik" for the production of fuel mixtures with rapeseed oil. It was mastered the production of a fundamentally new type unit "DEKCHER" that produces a fine rubber powder - full raw material for new products. It is designed as a chopper type of "Schroeder". Both of these machines are included in the flow chart developed by the full cycle of rubber waste, and the plant is ready to ensure its proper equipment.

Thus, despite the economic crisis of the late twentieth century the Open Joint Stock Company "Research and Production Enterprise Bolshevik" retained universal technological capabilities, its basic specialization and continues to hold for a number of products monopoly in the CIS countries, and with certain types of products competing on the world market with highly technically countries. Most of the products produced by RPE "Bolshevik" are not produced by any enterprise in Ukraine.