The more rare exhibits the more interesting the exhibition. In the "Electronics" section of State Polytechnic Museum the attention is attracted by the world's first ultrasonic motor, which was developed in Ukraine in the Kiev Polytechnic Institute. The history is as follows.

Back in the early 60s the Head of the Department of dielectrics and semiconductors electronics faculty of Kiev Polytechnic Institute Nekrasov Mikhail Makarovich, looking out in the flow of technical and scientific news for essential, namely, that could bring the invention into practice, offered undergraduates and graduate students to undertake a study of an idea. However, as it writes in his memoirs Catherine Lubenets, "most of his ideas, of course, vaporized, some dried up in the course and diploma works and projects. But it happened that some of them gave real results. Once Michael Makarovich decided to create ultrasonic motor.

He made the proposal to many graduate students. Reading the literature, making some test-experiments –all of them have refused.

Then, finally the third-year student Viacheslav Lavrynenko, also “crazy” like Nekrasov, agreed. He worked on this topic on the fourth, and the fifth year. Delved into the scientific literature, picked the right components, manufactured ceramics, made with pinpoint accuracy mechanical parts and in the defense of the diploma has demonstrated a working sample.

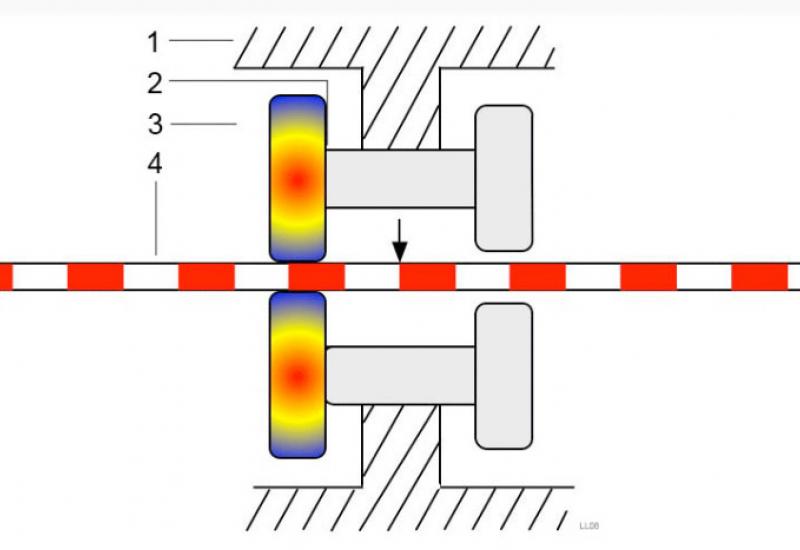

And so it was born a new type of engine, without any mechanical parts where the property is used piezoceramics change its dimensions under the influence of an electric field - the world's first ultrasonic motor.

And so it was born a new type of engine, without any mechanical parts where the property is used piezoceramics change its dimensions under the influence of an electric field - the world's first ultrasonic motor.

The main its advantages compared with the most common engine are smooth starting and stopping. In many designs of the ultrasonic motor this parameter time does not exceed 1 millisecond. Important in his work is that it is easy to manage, it accurately captures the correct position when you stop, does not contain magnets and does not create a magnetic field, can develop significant rotating (twisting) points - more than 10 N • m. Nominal frequency of rotation - 0- 3000 min-1.

Its design does not include a winding, collector brushes and contacts with can tear up. It does not pollute the atmosphere. When stopped it does not produce the power circuit overload. High frequency of power supplies provide simple, small volume and weight of electronic circuits and circuit speed control.

At the heart of the construction of the piezoelectric elements is polycrystalline material - ceramics. Solid performance of all parts of the piezoelectric motor ensures a low cost and a number of advantages in comparison with electro-magnetic analog: the lower complexity, manufacturing parts by stamping, pressing, casting; use of automatic and automatic lines. The design of ultrasonic motor wear-resistant materials ensured reliable operation for 1000 hours, and in some cases even 10,000 hours.

Piezoelectric engine - a new type of engine and can be used in recorders, tv devices, systems of automatic control and regulation, prostheses, toys, household appliances, etc. It was designed by Lavrynenko Vyacheslav Vasilyevich in 1964.

Patent protection of piezoelectric motors is provided by 27 patents of such developed countries as USA, UK, Japan, Germany, Austria and others.

Engine on display at our museum, was given to the 100th anniversary of the Kiev Polytechnic Institute, September 11, 1998 by the Faculty of Electronics.