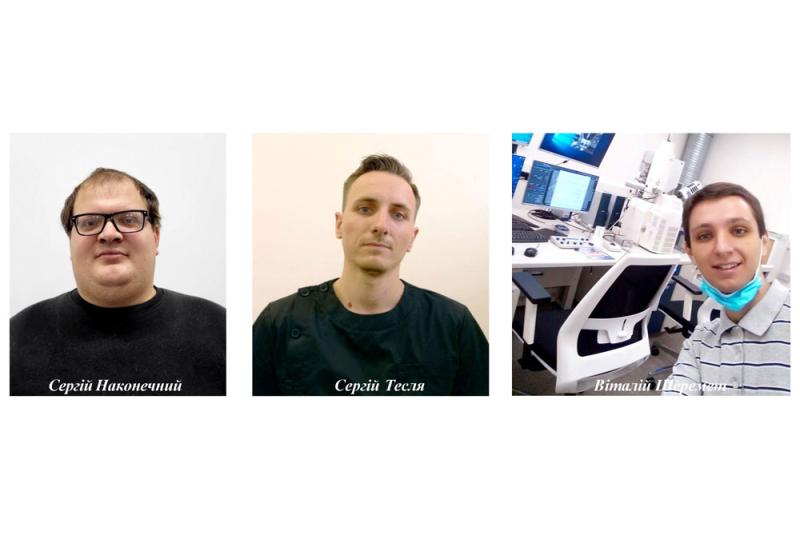

In order to encourage and support graduate students who have distinguished themselves in their academic and research work, the Ministry of Education and Science has introduced academic scholarships named after M.S.Hrushevsky. It is noteworthy that this year they were awarded to three PhD students from the Department of High Temperature Materials and Powder Metallurgy of the E.O. Paton Institute of Materials Science and Technology. After all, it is their developments and innovations that can improve the quality of products that are critically needed in our country today.

Sergiy Nakonechnyi is a third-year postgraduate student of the educational and scientific level of Doctor of Philosophy in Materials Science. His supervisor is Doctor of Technical Sciences, Professor Oleksandra Yurkova. Together they are working on the production and research of composite coatings based on a new class of materials - high-entropy alloys characterized by high hardness, strength, corrosion resistance, wear resistance, thermal stability, fracture toughness, etc. Scientists study the properties of coatings under normal and extreme operating conditions (dynamic and shock loads, high temperatures, etc.).

"The method of gas-dynamic spraying can be used to coat various parts and products, both during manufacturing and during the restoration of damaged ones, which are used in various industries, from civilian to military purposes," says the researcher. "In addition, the technology of cold gas-dynamic spraying can process products of various sizes - from small to large - in stationary and field conditions. You must admit that this is extremely important given the current enormous needs for production and repair work.

Sergiy Teslya is also a PhD student at the Department of High Temperature Materials and Powder Metallurgy. The main focus of his research work under the supervision of Professor Anatolii Stepanchuk is to study the patterns of production of powdered aluminum alloys with iron additives. Such alloys can be used to manufacture tribotechnical parts, i.e. those that operate under friction. Due to the presence of aluminum, the material has high thermal and electrical conductivity, so it is expected to be used for the manufacture of, for example, parts of current collectors (pantographs) for public electric transport.

Serhii is currently preparing to defend his dissertation. "The results of mechanical tests of the developed material show that the aluminum-iron alloy can be an excellent analog of the materials used today. In addition, the work also aims to reduce industrial waste, as aluminum with an iron content of more than 0.05% is currently considered a reject on an industrial scale," the scientist says.

It is worth noting that the study of the structure formation of aluminum alloys with different iron content is a hot topic for the world's scientific communities. This is evidenced by the high level of citation of the young scientist's research articles on the topic of his dissertation. To date, he has authored 5 articles and participated in about 10 scientific conferences where his results were presented.

Vitaliy Sheremet is also in his third year of postgraduate studies in Materials Science. His supervisor is Iryna Trosnikova, PhD, Associate Professor. His dissertation is devoted to the study of the impact of cold isostatic pressing on the characteristics and properties of materials used in extreme processing conditions. The high isostatic pressure processing technology makes it possible to produce tooling, structural materials, as well as special-purpose materials with a high level of properties during the operation of these materials in extreme conditions.

"The opportunity to work on the latest research equipment, knowledge and experience gained from mentors - representatives of the leading material science schools of the E.O. Paton Institute of Materials Science - are embodied in the development and creation of unique materials in demand in critical industries," says the graduate student.

In general, experts believe that Ukraine has every chance to become a country that generates innovations. And it's time not only to generate interesting ideas and implement quality projects, but also to create new services and products using our own resources and grants. The synergy of business and science has great prospects both in these difficult times and in the future.