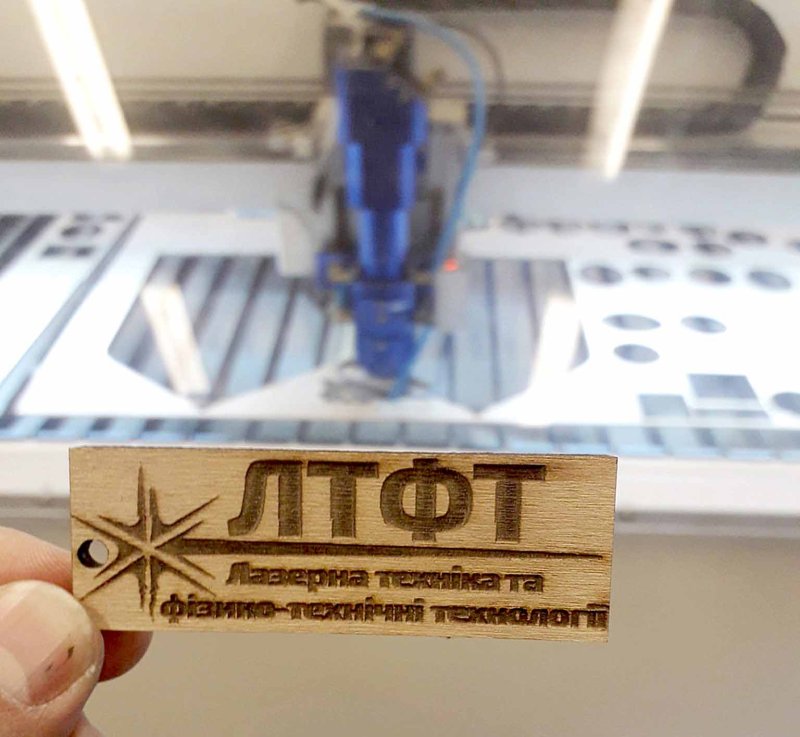

This publication is devoted to the 40th anniversary of the founding of the Department of Laser Engineering and Physical and Technical Technologies (LTFT) of the E.O. Paton Educational and Research Institute of Materials Science and Welding.

A KP correspondent discussed some interesting facts from the history of the only department in Ukraine where scientists, engineers and students are engaged in special methods of laser processing of materials with the head of the LTFT department, Candidate of Technical Sciences Oleksiy Kaglyak and Associate Professor Viktor Romanenko.

The potential accumulated by the LTFT team is very significant. After all, the cutting edge of modern science is marked by the latest technologies, including unconventional methods of material processing.

In Ukraine, the first research in the field of laser radiation for material processing was started in 1964 at the Department of Mechanical Engineering Technology of the Faculty of Mechanical Engineering of the KPI. They were initiated by Professor S.O. Kartavov. It is worth recalling that the laser itself was invented three years earlier, in 1961. The development of these studies in KPI was further promoted by the corresponding member of the Academy of Sciences of the USSR Prof. P.R. Rodin. The then graduate student of the department V.S. Kovalenko assembled the first laser technological installation in Ukraine for flashing microholes. Later he organized a research laboratory of laser technologies at the department.

The team of young researchers began to carry out state budget projects, research and development projects commissioned by industrial enterprises using the first laser technological installations created by themselves. One of the first operations to be developed was the laser piercing of holes in diesel injectors, flow washers, and many other products in the engineering industry. In addition, in the 1970s, the company began researching the possibility of using laser radiation to process (cut and split) natural diamonds. In addition, one of the enterprises in Dnipropetrovs'k (now Dnipro) fulfilled the terms of reference and introduced into production the process of making holes in metal molds using lasers for gas exhaust during tire vulcanization in heavy-duty vehicles. At the same time, a number of other processes were developed and put into production, such as the electric laser manufacturing of counter-bore holes in aircraft body nuts to prevent them from loosening, the process of manufacturing holes for the de-icing system of wing elements and the aircraft fire system, etc.

Overcoming the disbelief in the future of laser technology that existed at the time, which was typical for many scientists and machine builders, the staff of the newly created laser technology laboratory performed laser dimensional machining of parts, laser hardening and alloying processes on the surfaces of machine parts and metal cutting tools. At the same time, the processes of laser cutting of materials were studied. The results of scientific research and the implementation of their results in production were covered in various publications and presented at conferences of various levels. A significant role in popularizing new laser technologies among the industrial and scientific community of Ukraine, as well as the republics of the former USSR, Great Britain, the United States, Germany, China, Japan and other countries, and familiarizing them with the results of the laboratory's research was played by its head Volodymyr S. Kovalenko (1941-2022).

Between 1985 and 1990, the laboratory was equipped with pulsed solid-state lasers of the Kvant series. Moreover, the laboratory was equipped with emitters of technological lasers on an alumina garnet, which operated in continuous and pulsed generation modes. Powerful CO2 lasers were also introduced (among the first in such laboratories). Later, these emitters were equipped with focusing and coordination systems.

The laboratory staff paid considerable attention to inventions in the field of special laser equipment. Scientists and engineers also worked for the defense industry, although the work in this area was, of course, classified. This experience allowed the laboratory's specialists to introduce a wide range of laser technologies at many enterprises in Kyiv, Ukraine, and the former Soviet Union: from strengthening cutting and stamping tools to cutting and separating various hard-to-machine materials. For the widespread introduction of these operations in various industries, the department's staff was awarded the Council of Ministers of the Ukrainian SSR in 1990 and 1991.

Thanks to the technological developments of the laboratory, large plants in the country began to introduce laser operations into the production process. New technologies made it possible to speed up and reduce the cost of a number of operations for the manufacture of various products and convincingly proved the feasibility of introducing laser processing technology for tools, parts and products.

Later, it became quite obvious that it was impossible to ensure the rapid development of laser technologies without training of professional staff, so in 1984, at the Department of Chemical Production Automation of the Faculty of Chemical Engineering, on the initiative of Professor Volodymyr Kovalenko, a new engineering specialty "Technology and Equipment for Laser Processing of Materials" was launched for the first time in Ukraine. It was then, 40 years ago, that the Department of LTFT began a new stage in the history of its activities on the basis of the Kyiv Polytechnic Institute. In 1990, in accordance with the progressive trend of combining general engineering and graduate departments, the graduate department of laser technologies, machine design and material science (LTMS) was opened on the basis of the general engineering department of materials science and technology of structural materials (MTSM). It was headed by the Dean of the Faculty of Chemical Engineering, Doctor of Technical Sciences, Professor V. S. Kovalenko, a prominent Ukrainian expert in the field of laser technology and special methods of material processing.

At the graduate department of LTCM, research in the field of laser and combined technologies was effectively combined with classical research in the field of mechanical engineering and metal technology (design of various mechanisms, machines, methods of foundry, stamping, etc.)

In 1999, the Department of LTCM was included in the Mechanical Engineering Institute (MEI), created on the basis of the Faculty of Mechanical Engineering. In 2009, the department received a new name - "Laser Engineering and Physical and Technical Technologies" (LTFT). Professor Leonid Fedorovich Golovko was appointed acting head of the department. In 2010, the department was headed by Academician of the National Academy of Sciences of Ukraine, Doctor of Technical Sciences, Professor Igor Vitalievich Krivtsun.

The arrival of I.V. Krivtsun to the department was marked by the revival of research work, the development of scientific ties and close cooperation with industrial enterprises and the improvement of the functioning of the departmental laboratories. In 2020, the E.O. Paton Institute of Materials Science and Welding was organized, which included all the departments of the Faculty of Engineering and Physics, two departments of the Faculty of Welding and the Department of Laser Engineering and Physical and Technical Technologies. In the same year, Professor I. V. Krivtsun was elected Director of the E.O. Paton IES, and Associate Professor Oleksiy Dmytrovych Kagliak was appointed Acting Head of the Department of LTFT.

40th anniversary of the LTFT department

In 2023, Doctor of Technical Sciences Ihor Anatoliyovych Volodymyrskyi became the Director of the E.O. Paton Institute of Mechanical Engineering. During the election of the new director, the staff of the LTFT department voiced a new original idea to create a so-called "scientific Ramstein" (by analogy with the working international Ramstein coalition, whose members provide advanced weapons to the Armed Forces of Ukraine). The idea of such a "scientific Ramstein" is to help provide advanced equipment from Western countries to Ukrainian scientific institutions. Scientists and engineers of the LTFT department believe that this approach will accelerate Ukraine's integration into the European scientific, educational, economic and industrial space.