As Kyiv Polytechnic has already reported, recently Igor Sikorsky Kyiv Polytechnic Institute, Metinvest Holding LLC and Metinvest Polytechnic Technical University LLC signed a memorandum on the organization of partnership and cooperation in the field of educational, scientific, scientific-technical and innovative activities. Among the main areas of cooperation - the joint implementation of Igor Sikorsky Kyiv Polytechnic Institute and Metinvest Polytechnic Technical University LLC research, development and other types of scientific work commissioned by Metinvest Holding LLC on the basis of separate agreements.

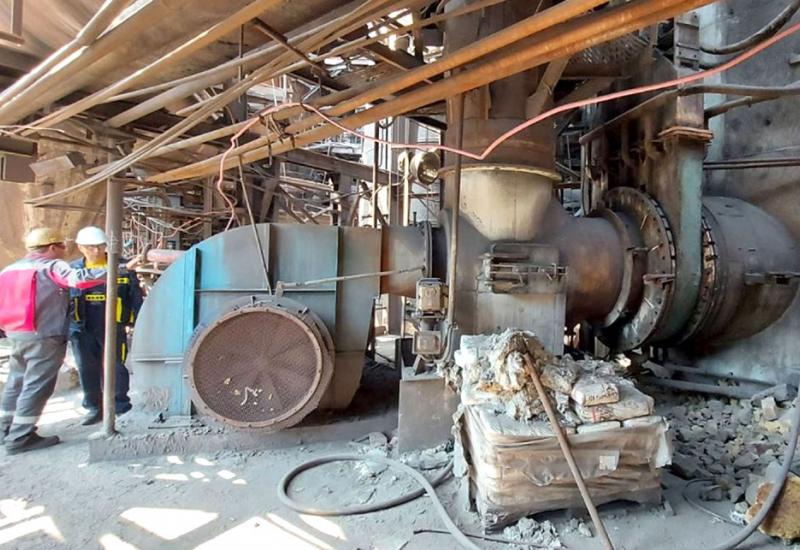

Mykhailo Abdulin, Doctor of Technical Sciences, Professor of the Department of Heat Power Engineering, told KP about this direction of cooperation: "Scientific connections of the heat and power engineering faculty of Igor Sikorsky Kyiv Polytechnic Institute with the enterprises of metallurgy of Ukraine and directly with LLC Metinvest Holding exist for a long time. At the end of the last century, the staff of the Department of Automation of Heat and Power Engineering Processes carried out a large amount of work at the Yenakiieve Metallurgical Plant. And already in the early 2000s, we can say, a new stage of cooperation between Kyiv's thermal power companies and metallurgists began. The combustion laboratory, headed by Doctor of Technical Sciences, Professor Volodymyr Khrystych, has created a universal jet-niche combustion technology (JNT), which is widely used in various industries of Ukraine. Currently, chemical furnaces, grain and pulp dryers, contact water heaters, Teplokomunenergo boilers, large power boilers (more than 1000 facilities in total) are being modernized on the basis of modern high-efficiency technology under the leadership of Mykhailo Abdulin and LLC “JNT” Supervisor Gennady Dvortsyn (this company employs employees, graduates and students of the Faculty of Heat and Power Engineering). During 2003-2008, dozens of different facilities of Public company "Zaporizhstal" were equipped with burners based on JNT. These are all open-hearth furnaces, mixers, all posts for drying and heating of steel shafts, sinter furnaces, etc. Fuel savings ranged from 20% to 60% for various facilities.

In addition, a significant improvement in the quality of the technological process, environmental safety and reliability of the equipment is provided. More than two dozen furnaces, heaters and stands for drying and heating of steel ladles with a significant environmental and economic effect were modernized in recent years at the enterprise of Public company "MMK named after Ilyich" in Mariupol. All fire-fighting facilities where gas is used have been modernized at the "MMK named after Ilyich” sinter plant. Thanks to JNT complex technological processes are considerably improved. For example, the properties of JNT make it possible to bring the vault of the furnace closer to the sinter, which will significantly reduce the specific fuel consumption per unit of output.

The success of Igor Sikorsky Kyiv Polytechnic Institute heat engineers does not go unnoticed at other enterprises in the metallurgical industry. For several months now, the management of Public company "Dnipro Metallurgical Plant" (m. Kamyanske) together with heat engineers develops plans for radical modernization of blast furnace production.

At the time of signing the memorandum we mentioned at the beginning of this article, rector of Igor Sikorsky Kyiv Polytechnic Institute, Academician of the National Academy of Sciences of Ukraine Michael Zgurovsky pointed out: "Signing the memorandum is in line with our strategic goal. Responding to the challenges facing "Metinvest Holding” LLC, we will improve start-ups and innovative projects that our scientists are working on, and in this way we will achieve common goals. “