Dmytro Mykolaiovych Lorentso was one of the most outstanding representatives of the engineering elite of the XX century, who determined the face and fate of the cargo rail carriage engineering in the USSR. He had foreseen the perspectives of the development of his field for decades. His ideas and projects were introduced in the middle of the previous century, moreover, even these days scientists and designers refer to his ideas and projects. That is why the report to his 110 anniversary at the Ural Rail Carriage Works was called “A Man Who Was Ahead of His Time” and nowadays scientists have called the period of his fruitful activity as a chief constructor at the mentioned plant from 1935 to 1959 Lorentso’s Era. Moreover, recently, under that very name – “Lorentso’s Era” - in the year of the 120s anniversary of the outstanding engineer and chief constructor at the Ural Rail Carriage Works, an excellent book, based on documental materials, by Nadiia Pershailo and Sergii Ustiantsev was published; in that book the introduced below information about the development of the domestic cargo rail carriage engineering, the experience of Lorentso’s creative activity as the founder of the Ural School of Rail Carriage Engineering, the scale of application of whose developments concerned the whole USSR, is demonstrated.

In particular, D.M. Lorentso himself wrote about his work, ‘The railway transport is said to be the most conservative field of the national economy. At first sight that seems to be true: railway tracks are the same as one hundred years ago; double-rail carriages look exactly the same they did 2030 years ago. But, to the point, the railway transport, including its rolling stock, is being constantly improved and changed.’

The Era of Engineer Lorentso started in the KPI

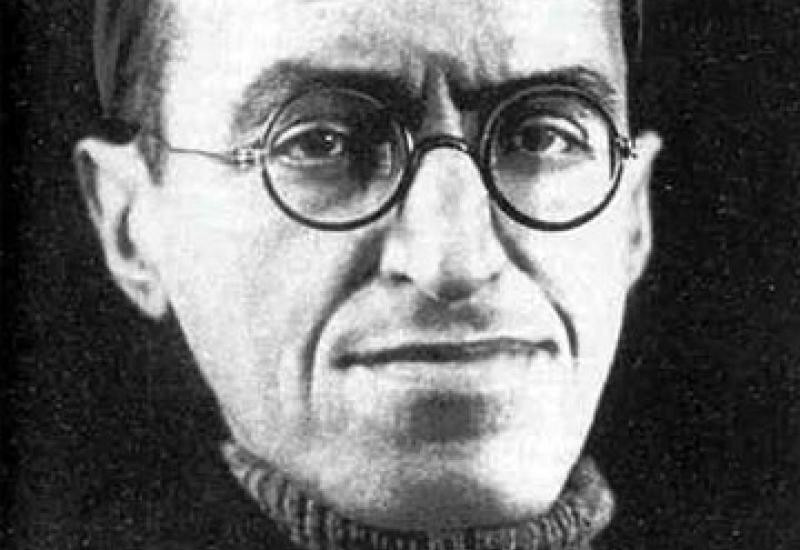

Who is Dmytro Lorentso? By origin he is from Russified Italians, he was born in Russia, graduated from Kyiv Polytechnic Institute and started his career in Ukraine.

From the very first years of his activity Kyiv Polytechnic set up a tradition, due to which a cohort of outstanding scientists and talented educators made from KPI students professional engineers who, according Dmytro Ivanovych Mendeleev’s precise evaluation, possessed a body of theoretical knowledge combined with their own researches.

The KPI student 1913-1321 Dmytro Lorentso studied bridge engineering at Yevgen Oskarovych Paton; professor Georgii Georgiiovych DeMets taught him physics and history of science and technology; professor Vasyl Petrovych Izhevskii taught introduction to metallurgy and, in particular, blast-furnace production; professor Kostiantyn Kostiantynovych Syminskii from 1914 to 1932 headed the Department of Strength of Materials and taught Lorentso introduction to structural mechanics. Lectures and supervision of qualification project on Metal Forming were made by professor Yakiv Mykolaiovych Markovych and others. Therefore, there is a logical connection between Dmytro Lorentso’s sound basic education at KPI and subject matters of the scientific and research projects, initiated by him in the years of professional activity, such as:

1937-38 – study on low-alloyed steel for making carriages, research on butt and spot welding;

1941 – a prototype for automatic submerged arc welding at the Ural Rail Carriage Works, the influence of cold stamping on the strength of products and research on strength of welded spot joints;

1949-1950 – research on the static and impact strength of arc and spot welded joints in carriage knots of low-alloy steels.

Knowledge Needed by Country

Large-scale freight traffic, which accompanied processes of industrialisation of the USSR in 30s, required high-value carriages able to function under conditions of growing velocity and weight of trains. The situation was complicated by the fact that carriages were produced by few plants in the country and, herewith, carriages of the same type were built according to different drawings. This complicated essentially the production and possibilities of cooperation of typical joints and parts. Way out of a difficult situation was found by establishing the Base Leading Design Department at the Ural Rail Carriage Works and all other carriage works had to build carriages according to the drawings of this department. The mentioned department was headed by D.M. Loretso, under whose leadership during short period of time 400 drawings out of 410 were made over, after that in 1935 he was appointed a chief constructor at the Ural Rail Carriage Works; he occupied this position up to 1959. During this period more than 20 projects of cargo carriages for different purposes were designed. All railway transport – carriages, covered waggons, open waggons - had been unified until the 40s. The main activities of the design office under the leadership of D.M. Lorentso became: introduction of new materials (low-alloy steel, aluminium alloys) into carriage practice, application of structural stock, unification of cargo carriages and automation of technological processes, first of all, through electric welding.

Technological revolution in rail carriage engineering began with the shift to low-alloy steel. D.M. Lorentso wrote on that score, ‘The problem of steel in rail carriage engineering is huge. Therefore, a replacement of carbon steel with low-alloy one gives great economic benefit as a result of reduced metal consumption. Low-alloy steel is durable and resistant to corrosion. In addition, hot rolled steel can be substituted for cold-formed profiles, the production of which was put into effect only in the 50s. In the universal carriage design of 1957 75% parts’ weight was made of low-alloy steel.

An example of Dmytro Lorentso’s being ahead of his time could be a concept of all-metal waggons and its practical realisation. Deeply convinced that it is necessary to make all-metal constructions in order to improve durability and longevity of cargo carriages, yet in 1939 he drafted a project of eight-wheel all-metal carriage. Though, the first in the country all-metal open-waggon was produced on 7th March 1975 after D.M. Lorentso’s death on 21st July 1968.

The history of the universal carriage construction indicates D.M. Lorentso’s professional understanding of the rail carriage development tendencies. D.M. Lorentso understood undeniable advantages during its exploitation pretty well, first of all, in minimisation of empty mileages thanks to the possibility of transporting various cargoes, such as grain, metal, overall construction etc. Despite there was no task of construction, Ural scientists designed and built the first waggon on their own initiative. When the first waggon was delivered to Moscow for performance testing, it disappeared… And only 10 years later, when the information about the design of such waggons in the USA, France and other countries appeared in foreign journals, Ministry of Railways ordered the Ural Rail Carriage Works to design a universal waggon for various cargoes transportation. The Ministry task was completed shortly since constructors had been morally and professionally ready for this long ago. The first universal waggons appeared in 1954. During the next years their design had been improved, particularly, with the help of aluminium alloys and, as a result, the universal waggon of Ural constructors was considered one of the best after the publications about it in Germany and Great Britain.

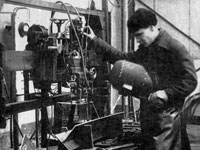

An automation of many carriage technological processes in the 30s was based on electric welding, which itself went through periods of development, improvement, progress and introduction into different spheres. Particularly, when solving specific tasks the decisions about this or other welding technique were ambiguous. Revealing in this regard is a letter by academician Y.O. Paton and his companion H.V. Raievskii, which was sent to D.M. Lorentso on the 22th June 1940, ‘The contrasting of arc welding to contact welding is also wrong. Each of them has its own sphere of reasonable application. Undoubtedly, for instance, the welding of sheathing should be made with the help of spot welding. On the other hand, it is doubtful that frame joints should be welded with the help of spot welding as it is stated in the drawings.’ Therefore, relationship between teacher Paton and student Lorentso during his studying at the KPI logically resulted through years into the relationship “academician Paton – chief constructor Lorentso”. By the way, it is worth mentioning that that was at the Ural Rail Carriage Works in Nizhny Tagil, where during the Second World War 25000 tanks T34 were produced after the large-scale application of Paton’s automatic arc welding.

An Extremely Honest and Modest Man

These are Lorentso’s certification characteristics as an engineer. His companion, Lenin Prize Laureate Mephodii Veremiev, who had long been working by his side, stated,’Lorentso is an engineer of the highest qualification. He knew the technology of producing carriages brilliantly. He had a nose for everything new and trained his staff according to this his quality. He was fanatically devoted to his work. And he was strikingly modest.’

Here is an example of his devotion. During war, evacuated and working near Barnaul and later in Dniprodzerzhinsk, Dmytro Mykolaiovych kept all design documentation since his department was leading in the sphere and cords were of the utmost importance. Moreover, during evacuation a work on designing new carriages continued and among them there was an all-metal waggon weighing 58 tons. The documentation of this waggon happened to be passed over by the authors in 1944 to the Ministry, then, after the liberation of Hungary, without the knowledge of the authors, it was given to the carriage plant in that country. And only in 1950 the Hungarian waggon accidentally appeared in Nizhny Tagil. During its examination the plant director said to his specialists,’ Here, look, how the waggons should be made!’ The authors of the design, who were present at that moment, answered their executive, ‘Ivan Vasilievich, the wagon is ours… We designed it in Altai and in 1944 took drawings to Moscow…’

One more example of high authority, professionalism and modesty of Dmytro Mykolaiovych. When Ministry workers were looking for possible workers to create a waggon for space industry, there was a legend, that this post was first offered to D.M. Lorentso who accepted it immediately. The plant director had to agree and he only said, ‘In case of failure, director will be punished, in case of success, Lorentso will be rewarded!’ Certainly, specialists at the Ural Rail Carriage Works completed the Ministry task, creating means for liquid transportation for space industry purposes. And in respect of awards, the chief constructor D.M. Lorentso for all his work received only a medal ‘For Hard Work in the Great Patriotic War 1941-45’ and a badge “Honorary Railwayman’. That is why after more than 40 years after the death of the outstanding engineer and constructor contemporary recognition of Dmytro Mykolaiovych achievements by compatriots are regarded as Lorentso’s Era. CEO of the public limited company Scientific Production Corporation “Uralvagonzavod” in his greeting to the current scientific reading participants O.V. Siienko said, ‘The results of Lorentso’s work are of great importance to all railway engineering in Russia and CIS. And hardly could “Uralvagonzavod” be the leading freight rolling stock producer on ‘the pace 1520’ if it had not been for the designs of this talented designer.’

Recently a corporate prize ‘Lorentso Prize Laureate’ for outstanding work, inventions and achievements in the field of carriage engineering has been established. The most successful students of the Ural National Technical B.M. Yeltsin University receive Lorentso’s Grant. Thereby, a good memory of an outstanding constructor is cherished and multiplied by the best representatives of new generation of compatriots.

Main milestones of his life and creative work

Lorentso Dmytro Mykolaiovych was born on 4 November, 1892.

1913-21 - studying at NTUU “KPI”.

1925 – takes part in reconstruction of Rail Carriage Works “Krasnyy Profintern” in Bezhytsia Town (Bryansk Region).

1931 – transferred as technologist to Ural Rail Carriage Works in Nizhniy Tagil.

10.05.1935 – Lorentso was appointed the design manager at Ural Rail Carriage Works.

1937 - design office of Ural Rail Carriage Works was defined as the main in USSR in development of the main types of eight-wheel high-capacity cars (all wagons except special-purpose cars).

1937-38 – The project of gondola for the direct international connection with axle-changing.

1938 – Weighing 100 ton gondola cars were applied in industry for the first time in the USSR.

July 1940 – application of automatic arc welding with bare electrode under layer of flux began on Ural Rail Carriage Works’ initiative (unit was developed by Institute of Electric Welding in spring 1940).

1941 - Ural Rail Carriage Works produced 11900 boxcars, gondolas and wagons. Production reached 70 cars per day (the biggest quantity during pre-war period).

In autumn 1941 – Production of cars was stopped. Ural Rail Carriage Works was transferred to the possession of People’s Commissar of tank industry. Lorentso was evacuated from design office to Barnaul, then he was sent to renew “Vagonka” in Dniprodzerzhins’k.

October 1945 - Ural Rail Carriage Works started to renew production of wagons. First cars were constructed by unified plans and engineering factors of 1941.

December 1945 - headed by Lorentso who played a great role in renewal of industry, design office returned to Ural Rail Carriage Works.

Since 1945 – Tank production technologies were applied into wagon production. Technology of wagon casting was created after the example of tank parts casting; new steel grades, multiple tooling, mechanized welding were used.

1947 - Gondola cars of low-alloyed steel were introduced into industry for the first time in USSR.

1948 - Ural Rail Carriage Works started to launch boxcars.

1953 – There were created new task groups for designing cistern for liquid oxygen shipment.

1954-55 – Wagon for farm machinery and car shipment.

1954 – Carryalls with sliding roofs were produced for the first time in USSR.

1959 – Lorentso Dmytro Mykolaiovych resigned his position of design manager.

Il’chenko M.Y., academician of National Academy of Sciences of Ukraine (Speech at Scientific reading in cycle “Outstanding designers of Ukraine at NTUU “KPI” 6.11.2012)